A Flying Car - My Design

About a year ago, I read a magazine article about inventors trying to come up with a workable flying car that could sell for about the price of a luxury SUV. In other words, a small plane that can take off from a driveway or very short road, and be safe, maneuverable, and seat 4 people plus a little luggage, and still be under $50K to buy.

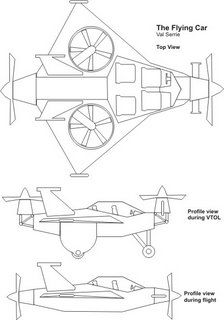

There were a number of designs, but they all had flaws. Too heavy. Too expensive. Not enough lift. Not small enough. Not big enough. Too complicated – whatever. I looked at the problems they were having and I had a solution. I had a creative idea for a design for one that would in fact work. It is simple, and comparatively inexpensive, and I actually took the time to draw out the design of it, which you see here.

This design has a way of creating the lift from a standing position, and then convert into forward motion at speed, while keeping costs down.

What this shows is a wide-fuselage, short-body propeller plane (jets are expensive) which essentially acts like a helicopter for take-offs and landings, and a plane for linear flight. There are vertical propellers in the wings, and a propeller at the front and the rear which swivel vertically to provide a 4-point helicopter style lift. You’ve seen military helicopters taking large cargos with two propellers. One front and one aft. Well, this has that and two more – one on each side. Once airborne, the front and rear props swivel back into horizontal position and now act as a pull and push mechanism with counter-rotating blades, to fly at higher speeds than a helicopter can.

There are four main motors. One fore, one aft, and two in the rear fuselage which run the two wing rotors by belt/chain drive (to keep a low wing profile for aerodynamic purposes)

There is even a camera shutter-like closure for the tops of the wings and a solid closure on the underside of the wings to close off the wing rotors during higher-speed horizontal flight and provide smoother, quieter flight, and more lift. Landing gear is integrated into the swivel front propeller so that when the motor is front-facing, the wheel is tucked up and away, but when the motor is up and lifting, the wheel is down. Similarly, when the wing rotors are being used, the covers are open and down, and the wing wheels are mounted on them. When in flight, those covers are closed and so the wheels are tucked up out of sight. Seating is 4 people + luggage behind the second row of seats.

This allows a person to take-off and land from a driveway, and commute long distances into a city – or other cities. Wherever they need to be. Live in a rural setting, on less expensive land, and still have a big city job with the associated income. The best of both worlds.

I realize that I don’t have the funds and facilities to be able to make this up myself, and I have had an extremely busy year for various reasons, so I was not able to create the working model prototype yet. I need someone to help me: a partner with the means to help make this vision a reality. The design will work, and I have included the core of it here, however, I will say that I have deliberately made two fundamental flaws in this design so that it is not stolen and used by someone else. There is enough of the idea shown here to show essentially how it works. Enough to garner interest, however not enough to have a working model. Two pieces are missing (at least). These will not be immediately discovered, but are crucial and integral to the design. It will be un-flyable without them, and if left out, they cannot be added later without a complete rebuild and redesign.

If you are interested in pursuing this in partnership with me, please send me an email.

10 Comments:

For a humorous look at the flying car, watch this short film by Kevin Smith:

http://www.viewaskew.com/tv/leno/flyingcar.html

Val,

Your productivity puts me to shame. If only we could put all of our dreams into reality.

Thanks, Robert. That was hilarious! So funny.

I may not be a gay German scientist with a twisted fetish for amputating feet, but I do think this design will work well. LOL

Ptelea: My productivity is nowhere near what I'd like it to be. Things that I think ought to take me just a few days, end up taking months. There are SO many things I want to do and complete and I just don't seem to get the time.

I have an idea that can stop virtually all train crashes and derailments, but I've been sitting on it for years because I haven't had the time to pursue it. I don't want to give it away, so I have to have some way of packaging the idea in such a way that once the railroad company sees how it works, they don't steal it. I need a way to capture their interest and present it without giving it away.

I think I'll do a quick post on that.... but not explain it. Tricky.

I have an idea that can stop virtually all train crashes and derailments, but I've been sitting on it for years because I haven't had the time to pursue it. I don't want to give it away

why not just patent it?

Igor,

I was told it would cost me $6,000 to $10,000 for a patent attorney to be able to search and file the patent properly.

I didn't have the money for that, so it waits until..... Well, I wonder if I ever will.

But it is such a great idea. Eventually someone else will have the idea.

That has happened to me already with other things.

I came up with an idea for making glass darken electronically, by embedding lines of LCD in the glass, and as the rheostat is turned up, more lines of LCD are darkened. 5 dark lines per 10 would be 50% tint, 2 lines per 10 would be a 20% tint, etc.

I didn't act upon it, and now it's been invented by someone else. The new Ferarri has it in the roof - exactly the application I first thought of it for!

I'm still kicking myself over that one.

v

I mean it's easier to find a partner for patent (your idea, her money), then a partner for the business...

ok, 2 fundumental flaws... two...

the first one seems obvious - the push propeller has to change thrust vector 180degrees when converting from verical to linear flight.

the second.... I'd say that as front - rear propellers do not seem to have transmission connection - then if either front or rear motor goes out during vertical flight - the car becomes unstable and crashes.

am I close?

You are 50% there.

1) You are correct - the rear propeller has to be a push for linear flight, therefore it cannot be a pull to pull it up in VTOL mode, and then suddenly switch to be able to spin in the opposite direction.

Therefore: Solution is: My real design has the rear propeller facing DOWN in VTOL mode and swings up for linear flight.

Imagine that the front prop and rear prop swing into position at the same rate which gives the craft a smooth arc trajectory from vertical to horizontal flight.

2) No. Stability is not a problem since single engine planes would have this same problem anyway, this in fact is safer on multiple levels. The rear fails, there is still the front. The front fails, there is still the rear. BOTH front and rear fail, there are still the two wing props from VTOL mode, that would still ease your landing.

Failing engines are not the problem.

The problem is side winds. Compensating for lateral forces. When a tradition plane takes off there is forward vector to compensate. When a helicopter takes off, the pilot can tilt the blades into the oncoming wind to compensate.

So I came up with a similar solution. The front and rear cones can tilt. That is, they rotate on their axis. Imagine the wind is strong and coming from the left(port side). Tilt the nose cone with the propeller facing up, toward the left so that it is now say, 45 degrees to the left. Facing into the wind and yet still providing lift. The tilt of the rear works in opposite direction, tilting to the right to provide push against the oncoming wind.

val

I probably hasn't conveyed my thoughts clearly enough about stability.

let's look at the car as it is hovering. we have 4 sources of thrust around the centre of mass directed up. when the car starts loosing stability, say, it pitches its nose up - then the rear propeller increases its thrust and the car is stable again. that's how VTOL crafts manage their stability when not in linear flight. Harrier has 4 sources of thrust around centre of mass. F-35 has the same configuration.

this mechanism is also used for turning the craft in the air.

now imagine the rear motor goes down - and now we have only 3 sources of thrust distributed UNEVENLY around the centre of mass - and NO thrust behind centre of mass line - thus they are unable to compensate - the craft crashes.

that's why all 2-propeller helicopters has a drive shaft that links both propellers to ensure the craft is not going unstable when one motor goes out - the remaining engine would turn both propellers thru the shaft. even V-22 Osprey has that kind of hard link between its propellers - which is quite an accomplishment given its configuration.

Unlike VTOL crafts, common planes use aerodynamic forces to control their stability - but this is only possible when flying fast, which is not an option for the hovering car as you have to have a high speed relative to air to start using aerodynamic forces...

i made a very similar craft. i was kinda shocked when i saw yours its the same general shape. where you have the two fans i have four in each corner that can pivot. if interested i have a 3d model.

Post a Comment

<< Home